Bursa Uludag University (BUU) Faculty of Engineering, Department of Civil Engineering Assoc. Prof. Dr. Ali Mardani's project ‘Development of Polypropylene Based Smart Fibres with Superior Performance, Pozzolanic Properties, Environmentally Friendly and Economic Polypropylene Based Smart Fibres that can be used in Cementitious Systems’ will pave the way for new developments in the construction sector.

BUU Civil Engineering Department Faculty Member Assoc. Prof. Dr. Ali Mardani's project was entitled to be supported within the scope of the Research Universities Support Programme (ADEP) under the category of ‘Smart and Innovative Materials’. Prof. Dr. Ali Kara from the Department of Chemistry, Faculty of Science and Letters, BUU, and Dr. Lecturer Süleyman Özen from the Department of Civil Engineering, Faculty of Engineering, Bursa Technical University. In the project, where Prof. Dr. Ali Kara from the Department of Chemistry, Faculty of Arts and Sciences, Prof. Dr. Süleyman Özen from the Department of Civil Engineering, Faculty of Engineering, Bursa Technical University and PhD student Yahya Kaya from the Department of Civil Engineering, BUU will work as researchers, it is aimed to increase the performance of fibres by surface modification with 12 different approaches that are more economical compared to the literature. In the study, it is also aimed to produce much more efficient fibres by providing pozzolanic properties to surface modified recycled fibres.

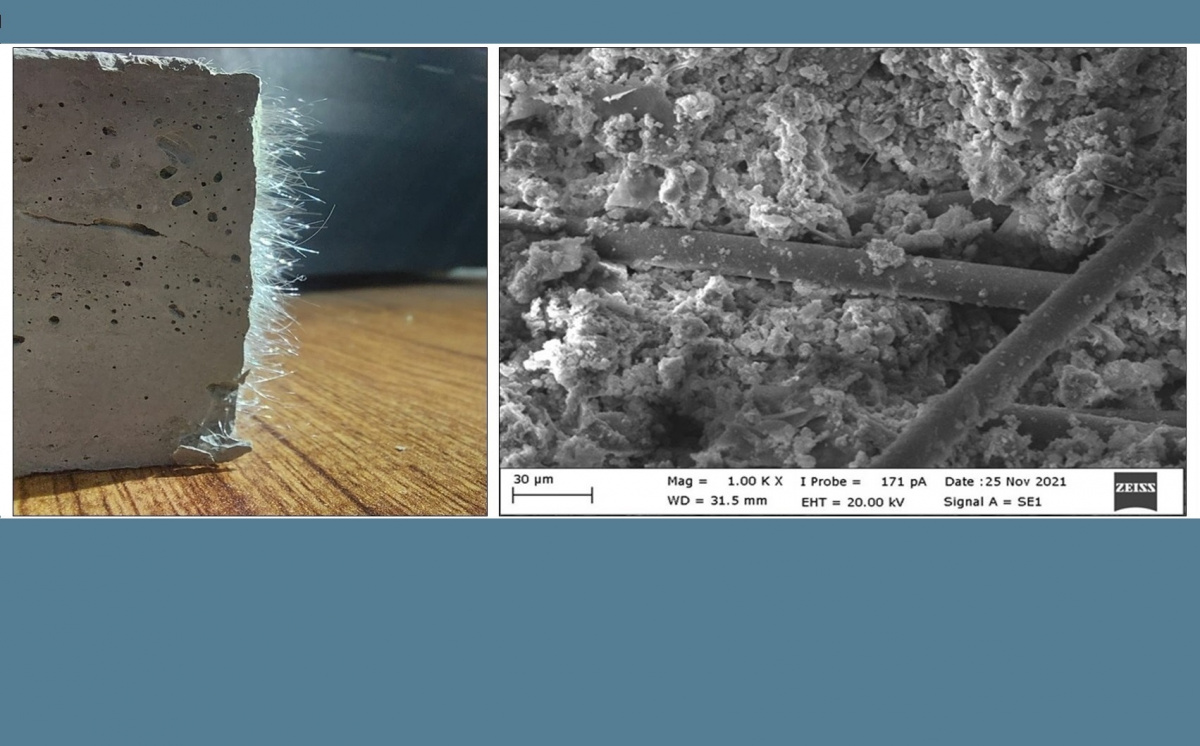

CRACK DEVELOPMENT WILL BE PREVENTED

Giving information about the project, Assoc. Prof. Dr. Ali Mardani said that they aim to produce environmentally friendly smart fibres with pozzolanic properties with high patentability potential. Mardani emphasised that they think that these fibres will provide better adherence with the matrix by using 12 different surface improvement methods within the scope of the project; ‘We also aim to reduce the void volume of the samples as a result of pozzolanic reactions that will occur by providing reactive silicon oxide on the surface of the fibre. In this way, we will ensure that the matrix and fibre work together as a monolith in the fibrous samples produced. Thus, crack development in the material will be prevented and ductile fracture will be provided instead of brittle fracture. In addition, thanks to the increase in the adherence of the fibre with the matrix and the pozzolanic reactions occurring with reactive silicon oxide, the effectiveness of the fibre will increase and improve the mechanical and durability performance of the samples.’

A total of 27 ADEP projects are being carried out at Bursa Uludag University, 8 in the Faculty of Engineering, 6 in the Faculty of Theology, 5 in the Faculty of Agriculture, 4 in the Faculty of Science and Literature, and 1 each in the Faculty of Medicine, Faculty of Veterinary Medicine, Faculty of Education and Orhaneli Vocational School.

You can access the ADEP projects running at Bursa Uludağ University here.